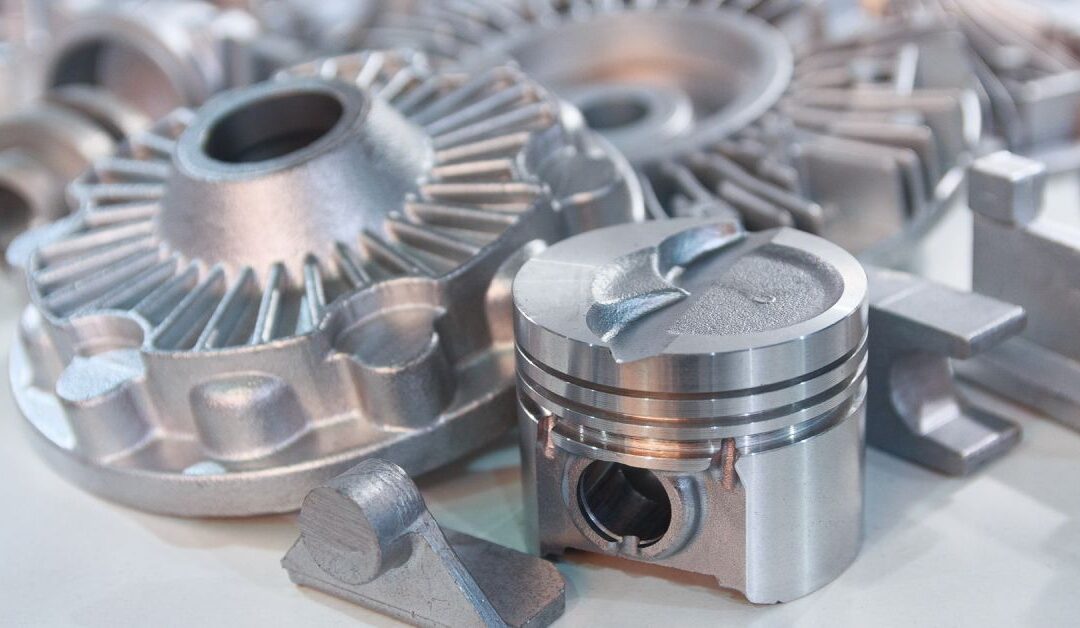

Metal Casting: Reducing Weight Without Compromising Strength

Wiki Article

A Consider the Future: Patterns Forming the Future Generation of Light Weight Aluminum Foundries

The aluminum shop industry depends on the brink of considerable change. Automation and progressed innovation promise to reshape manufacturing procedures. Sustainability practices are ending up being crucial to satisfy environmental standards. As customization demands climb, the requirement for adaptability in producing expands. Collective efforts with tech companions may drive technology. These emerging patterns suggest an essential shift awaits. What obstacles and chances exist ahead for aluminum foundries in this developing landscape?The Rise of Automation in Aluminum Foundries

The integration of automation in light weight aluminum foundries is improving the sector landscape. As suppliers embrace innovative modern technologies, procedures typically reliant on manual work are ending up being increasingly automated. This change not just enhances production efficiency but likewise lessens human mistake, bring about a more consistent item quality. Robotics and expert system systems are being made use of for jobs such as mold and mildew prep work, pouring, and ending up, enhancing procedures and decreasing lead times.Additionally, automation helps with the collection and evaluation of data, allowing shops to optimize their processes constantly. Predictive maintenance powered by sensing units helps in preparing for equipment failures, leading to reduced downtime. The labor force is also progressing, as employees are adjusting into duties that need oversight of automated systems, concentrating on higher-level analytic and advancement. Overall, the increase of automation in light weight aluminum shops represents a significant evolution, positioning the market for enhanced productivity and competition in a quickly altering market.

Embracing Sustainability Practices

Light weight aluminum shops are increasingly taking on sustainability techniques to address ecological problems. Key campaigns concentrate on recycling and reuse of products, together with technologies targeted at boosting power effectiveness. Aluminum Foundry. These efforts not just minimize waste but also add to a much more sustainable production processRecycling and Reuse Initiatives

A considerable change towards sustainability is reshaping the landscape of aluminum factories, with lots of embracing ingenious recycling and reuse efforts. This activity highlights the relevance of lessening waste and making best use of resource efficiency. Factories are progressively carrying out closed-loop systems, allowing scrap aluminum produced throughout manufacturing to be reprocessed and rehabilitated into the manufacturing cycle. Additionally, partnerships with local recycling centers facilitate the collection of post-consumer aluminum, better supporting lasting methods. By utilizing advanced arranging technologies and reusing approaches, these shops boost the high quality of recycled products, ensuring they fulfill market requirements. Generally, these initiatives not only reduce environmental effect yet additionally add to set you back savings, positioning aluminum shops as leaders in sustainable manufacturing within the metal market.Power Performance Innovations

Numerous light weight aluminum foundries are welcoming power effectiveness technologies as component of their sustainability techniques. These advancements include the integration of advanced modern technologies such as automation, synthetic knowledge, and energy management systems. By optimizing manufacturing procedures, foundries can significantly reduce energy consumption while keeping outcome high quality. Additionally, several are buying renewable power resources, such as solar and wind, to power their operations, additionally decreasing their carbon footprint. Using energy-efficient heaters and reusing heat generated during manufacturing is likewise coming to be commonplace. These techniques not just add to ecological sustainability yet also result in cost savings for shops. As the industry develops, the dedication to energy efficiency will likely play an essential role fit the future of light weight aluminum production.The Impact of Expert System

As the aluminum shop sector develops, the combination of expert system (AI) is coming to be progressively considerable. AI modern technologies are revolutionizing manufacturing procedures by improving functional efficiency and reducing waste. Predictive analytics, powered by AI, enables foundries to anticipate prospective devices failings, enabling proactive maintenance and decreasing downtime. Furthermore, AI-driven formulas improve casting styles, resulting in enhanced material utilization and enhanced item top quality.AI promotes real-time tracking of manufacturing parameters, enabling immediate modifications to maintain perfect conditions. This flexibility not only enhances product consistency yet additionally sustains energy-efficient techniques. By analyzing large quantities of information, AI can identify patterns and understandings that human drivers might ignore, driving constant renovation. As these innovations come to be extra accessible, the light weight aluminum factory industry is poised to leverage AI to accomplish higher precision and development, ultimately forming an extra lasting and affordable future in production.

Additive Manufacturing Innovations

Additive production is quickly changing light weight aluminum factories by improving layout abilities and allowing extra intricate geometries. This development not just permits for better imagination in product advancement however additionally facilitates cost-effective production techniques. As these innovations evolve, they assure to redefine typical manufacturing procedures in the industry.Enhanced Layout Abilities

Innovation in layout capabilities has changed the landscape of light weight aluminum foundries, particularly via the assimilation of additive production innovations. This innovation permits higher versatility in making complex geometries that were previously unattainable with typical approaches. Factories can currently develop lightweight structures enhanced for efficiency and performance, minimizing material waste and enhancing power effectiveness. Furthermore, the quick prototyping capacities of additive production allow quicker iterations and refinements, cultivating development in item growth. Cooperation in between layout designers and foundry professionals has likewise been reinforced, causing much more reliable communication and enhanced end products. As these technologies proceed to progress, the capacity for tailored remedies customized to details applications will certainly further redefine the future of aluminum shops.Cost-efficient Production Approaches

Emerging trends in affordable manufacturing approaches have reinvented the aluminum factory sector, particularly with innovations in additive manufacturing. This modern technology makes it possible for the fast production of complex geometries with lowered product waste, substantially decreasing expenses. By using 3D printing methods, foundries can create complex components that typical methods struggle to attain, boosting layout adaptability. In enhancement, additive manufacturing improves prototyping procedures, permitting quicker versions and faster time-to-market. These technologies not just enhance manufacturing performance yet additionally add to sustainability efforts by minimizing scrap. As light weight aluminum shops increasingly adopt these techniques, they position themselves to satisfy growing need while maintaining affordable rates, ultimately changing the landscape of light weight aluminum production.Enhancing Quality Assurance Measures

Many foundries are carrying out standard operating procedures and strenuous screening procedures. By promoting a culture of accountability and continual renovation, they aim to reduce variations in production high quality. Educating programs for employees are additionally being prioritized to protect that staff are fluent in high quality assurance methods. Inevitably, these boosted quality assurance determines not only boost product reliability however also reinforce the track record of light weight aluminum factories in an affordable market, leading the way for long-term success and sustainability.

The Shift In The Direction Of Modification and Flexibility

As aluminum shops improve their quality assurance steps, they are additionally responding to an increasing need for modification and flexibility in manufacturing - Metal Casting. This shift is driven by evolving client choices and the demand for specialized products across various industries. Shops are adjusting their procedures to accommodate lower quantity runs and customized designs, allowing them to fulfill particular client demands extra successfully. Advanced innovations, such as additive production and computer-aided design, are facilitating this change by permitting rapid prototyping and adjustments, therefore decreasing lead times. Furthermore, the combination of wise manufacturing techniques improves the versatility of production lines, permitting shops to pivot rapidly in response to market modifications. The focus on personalization not just boosts customer fulfillment yet additionally positions factories to remain competitive in a dynamic market landscape, leading the way for development and varied item offerings in the light weight aluminum sectorCooperations and Collaborations in the Market

Partnerships with study establishments assist in the advancement of sustainable practices and new alloys, attending to environmental issues and governing needs. These collaborations additionally help in expertise sharing, permitting firms to embrace finest techniques and swiftly execute technological improvements.

Calculated partnerships with vendors assure a secure supply chain for raw materials and advertise price efficiencies. As the market faces challenges such as labor lacks and enhancing competitors, these collaborations are pivotal in driving growth and technology. By interacting, aluminum factories can better navigate the intricacies of the market and attain lasting success.

Frequently Asked Inquiries

What Are the Initial Costs of Automating a Light Weight Aluminum Foundry?

The preliminary expenses of automating an aluminum foundry can range significantly, normally in between numerous thousands to several million dollars, depending upon the degree of automation, tools top quality, and particular functional demands of the center.Exactly How Can Small Shops Take On Sustainable Practices Efficiently?

Small factories can take on sustainable methods successfully by executing energy-efficient technologies, recycling scrap materials, enhancing processes to reduce waste, and using eco-friendly materials, cultivating a society of sustainability among staff members with training and awareness initiatives. Aluminum Foundry.

What Role Does Information Protection Play in AI Applications?

Information protection is crucial in AI applications, making certain the security of sensitive details, preserving individual count on, and avoiding unapproved access. By executing durable safety and security procedures, companies can safeguard information honesty and maintain conformity with regulations.Just How Will Additive Production Affect Conventional Casting Methods?

Additive production will enhance standard casting methods by permitting more complicated geometries, minimizing product waste, and shortening manufacturing times. This combination may result in a hybrid strategy, optimizing performance and expanding design opportunities in production.What Skills Will Be Many sought after in Future Aluminum Foundries?

In future light weight aluminum foundries, skills in additive production, data sustainability, analysis, and automation methods will certainly be paramount. Employees competent in environmentally-friendly processes and innovative innovations will certainly be in high demand, driving sector technology and effectiveness.Foundries are significantly applying closed-loop systems, permitting scrap aluminum generated during manufacturing to be reprocessed and reintegrated right into the manufacturing cycle. Additive production is swiftly changing light weight aluminum shops by boosting layout capabilities and making it possible for a lot more complicated geometries. Technology in design capacities has actually changed the landscape of aluminum foundries, specifically via the assimilation of additive manufacturing modern technologies. Emerging trends in affordable manufacturing methods have actually transformed the aluminum foundry field, especially with improvements in additive manufacturing. As light weight aluminum foundries enhance their top quality control measures, they are additionally responding to an increasing demand for customization and versatility in production.

Report this wiki page